The Advancements of Membrane Switch Technology in the Automotive Industry

The Advancements of Membrane Switch Technology in the Automotive Industry

Blog Article

Membrane Layer Change Technology: The Secret to Trustworthy and Cost-efficient User Interfaces

Membrane layer switch modern technology has emerged as a critical element in the design of customer interfaces, giving both integrity and cost-effectiveness across a diverse range of applications. As we discover the multifaceted benefits of membrane layer switches, their possibility for technology increases questions concerning future applications and advancing trends.

Comprehending Membrane Change Innovation

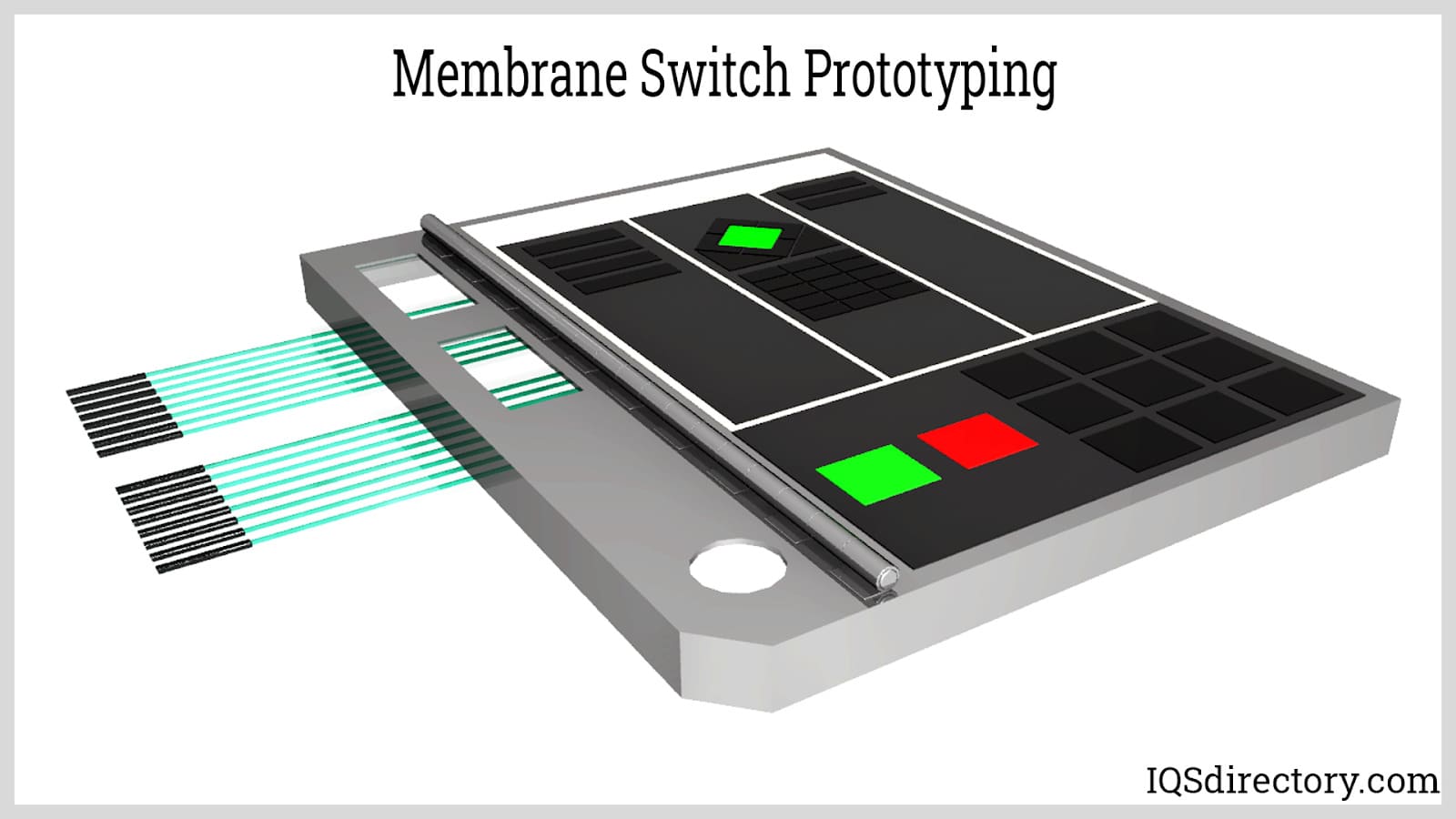

Membrane switch modern technology is a widely made use of interface service in various electronic gadgets, providing a seamless mix of functionality and style. This innovation incorporates several layers of materials, generally consisting of a graphic overlay, spacer layer, and a circuit layer. The visuals overlay displays the interface aspects, while the spacer layer separates the circuit layer from the overlay till an individual activates a button.

When pressure is related to the overlay, the circuit layer finishes the electrical circuit, sending out a signal to the gadget. This device enables various configurations, including responsive responses and backlighting options, boosting customer interaction. Membrane layer buttons are commonly produced making use of long lasting products such as polyester or polycarbonate, making sure durability and resistance to ecological elements like dampness and dust.

The adaptability of membrane layer changes enables their application in diverse sectors, including medical gadgets, consumer electronics, and commercial controls. Their small style allows for assimilation right into space-constrained atmospheres, giving a reliable interface without jeopardizing aesthetic appeal. Recognizing the intricacies of membrane layer switch technology is vital for producers and developers looking for to develop trusted and reliable human-machine interfaces.

Trick Benefits of Membrane Layer Buttons

While different interface remedies exist, membrane changes offer distinctive advantages that make them a preferred choice in countless applications. Among the main advantages is their resilience; membrane switches are created to endure rough environmental conditions, consisting of wetness, dirt, and temperature level fluctuations, making sure durable efficiency. This resilience significantly minimizes the need for frequent substitutes, consequently lowering general maintenance expenses.

In addition, membrane buttons are light-weight and portable, making them ideal for applications where space is restricted. Their inconspicuous layout adds to a smooth appearance without jeopardizing performance.

Cost-effectiveness is also a remarkable benefit, as the production process for membrane layer switches often tends to be less costly contrasted to conventional mechanical switches. This affordability, incorporated with their dependability and simplicity of installment, positions membrane switches as a practical solution for a variety of markets seeking effective and reliable interface.

Applications Across Numerous Industries

Just how do membrane buttons adapt to the diverse requirements of various sectors? Membrane button modern technology is progressively acknowledged for its convenience, making it appropriate for a wide variety of applications across numerous industries.

In customer electronics, membrane switches give a portable service for remote controls and home appliances, boosting individual experience via instinctive design. In addition, the commercial industry leverages membrane switches for machinery control board, gaining from their resistance to severe atmospheres, such as dampness and dirt.

Armed forces and aerospace applications likewise make use of membrane layer buttons for their dependability and capacity to hold up against extreme conditions, making sure operational efficiency in critical circumstances. The food and drink industry embraces these buttons for automated systems, where sanitation and simplicity of operation are critical (membrane switch). Eventually, membrane layer buttons are customized to satisfy the one-of-a-kind demands of each industry, proving their important duty in modern innovation interfaces

Layout and Personalization Choices

In the realm of membrane switch innovation, layout and customization options play a pivotal role in boosting performance and individual communication. These switches can be customized to fulfill specific operational requirements and aesthetic choices, making them versatile components in various applications.

Among the main customization alternatives is the design of the button itself, which can be made to suit one-of-a-kind interface and ergonomic considerations. By readjusting the shape, dimension, and plan of buttons, suppliers can develop instinctive Find Out More styles that facilitate simplicity of use. Additionally, the incorporation of different colors and visuals overlays enables for branding and boosted exposure, making sure that customers can promptly determine functions.

Moreover, membrane layer buttons can be crafted with various responsive responses mechanisms, such as elevated buttons or distinct clicks, to boost the user experience. Different products can also be selected for longevity and ecological resistance, resolving factors such as moisture, temperature level fluctuations, and read this article chemical direct exposure.

Ultimately, the extensive style and customization choices offered in membrane layer switch innovation equip organizations to develop tailored solutions that not only fulfill useful demands but additionally straighten with their branding and functional needs.

Future Trends in Membrane Layer Buttons

As membrane layer button modern technology remains to advance, future trends are significantly concentrated on improving user experience and integrating sophisticated capabilities. One go to the website significant trend is the combination of touch-sensitive and capacitive innovations into conventional membrane layer switches. This advancement permits more intuitive interface, offering responsive feedback while maintaining a streamlined layout.

An additional arising fad is making use of eco-friendly materials, driven by the growing demand for sustainable production techniques. Makers are looking for to reduce their carbon footprint by using recyclable substrates and low-impact inks, aligning with global sustainability goals.

Moreover, the rise of the Net of Things (IoT) is prompting the incorporation of smart functions right into membrane switches. Improved connection options will enable tools to connect with each various other, permitting smooth assimilation into more comprehensive systems.

In addition, innovations in printing technologies, such as electronic printing, are permitting higher style adaptability and modification. This allows suppliers to produce complex styles and dynamic colors cost-effectively.

Conclusion

Finally, membrane switch technology represents an essential technology in user interface style, using substantial benefits in toughness, modification, and cost-effectiveness. Its prevalent applicability throughout varied markets underscores its significance in modern-day innovation. As developments remain to emerge, especially in touch-sensitive interfaces and lasting products, the capacity for membrane changes to boost customer experience and capability remains appealing. Proceeded exploration of this modern technology will likely generate further improvements and widen its range in future applications.

Report this page